Energy savings in industry

technologies and solutions for improvement of energy consumption and quality

In the metalworking industry heating processes are key production steps. About 65% of the industry’s final energy requirement is expended on it.

Successful introduction of energy-efficient heating to operating practices by means of new and innovative processes is expected not only to reduce the energy requirement and the costs, but also to lead to an optimization of product quality and production processes.

Depending on their operational situation, companies have various options available to them for utilizing the energy contained in low-calorific gases. It can be used as process heat within the company or fed to neighboring customers.

Foundries can use the gases produced there in their own specially adapted CHP plant with high efficiency, working well with low-calorific process gases produced in the iron and steel industry (blast furnace gases).

Heating processes are decisive for the quality, costs, energy requirement and environmental impact of many products manufactured in the industry.

The objectives are to develop an accelerated and equally convective heat influx to the entire material used, optimized exposure and loading times for the furnaces and a reduction of unwanted physical and chemical processes such as negative effects of scale, surface decarburization and tension.

With regard to these objectives, several different approaches lend themselves to optimised heating processes:

- avoiding heat losses and recovering heat;

- exactly controlling the combustion gas composition;

- oxygen level and furnace atmosphere as well as linking individual measures to primary process management;

Our solutions and technologies

In order to achive above mentioned goals we offer following solutions and technologies:(please follow the links)

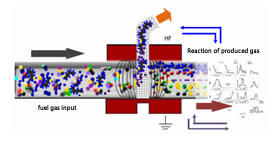

- Optimizer - a technical system for efficient utilization and combustion of gaseous fuels

Single, or combination of any of these technologies can result with significant increase of energy efficiency and energy savings in the industry

Environment

By far the greatest potential for CO2 and other polution gasses reduction in the industry is in efficient fuel combustion as well as in recovery and utilization of waste heat.

The comprehensive utilisation of these technologies in the industry is worthwhile since the energy costs and CO2 emissions sink and the cost-effectiveness improves.