Biomass Conversion

Efficient biomass and waste conversion to heat and power

Prior to any concrete project plans, the individual raw material situation has to be identified and assured in order to meet the proper objection of heat and power to be generated.

Thermal beneficiation of various wastes such as waste wood class A 1-4 requires for reason of better processing mechanical upgrading of the waste to suit better the thermal processes. As a matter of costs and thermal efficiency, physical upgrading is recommended.

Thermal process systems are mainly the fluidized bed and the grate incineration and combustion. As the most established ones the grate incineration system have been established due to their high flexibility in accepting a broad range of particle size and heating value, as well as fuels with low ash softening temperature.

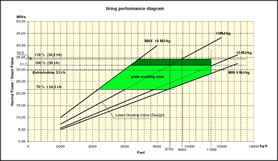

When the heating value of the waste is varying than water cooled system is rather recommended than an air cooled. Both systems have technical as well as economic advantages.

Thermal utilisation of biomass

Biomass from agriculture and forestry as well as from industrial processes, contain large amounts of thermally-viable energy. Use of this energy is, therefore, a sensible, environmentally friendly and carbon dioxide-neutral method of resource recovery.

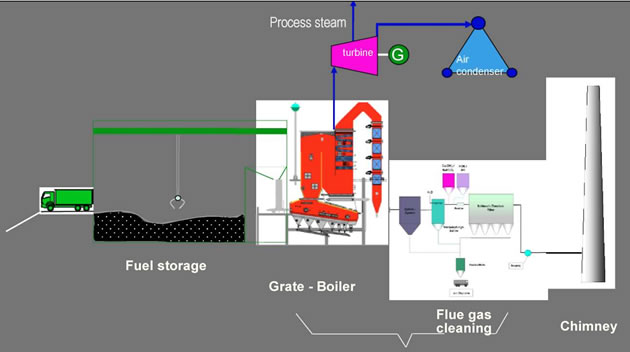

Using specially designed combustion systems, both polluted and unpolluted fuels can be incinerated optimally and converted efficiently to energy on an air-cooled or watercooled incineration grate. In this regard, the range of fuels includes renewable raw materials such as straw, corn (maize), class A1 to A4 wood, olive pips, pomace/marc residues, rice husks, arundo and other similar fuels.

The energy from the combustion process is converted to usable heat, such as process steam, in downstream plant components. Afterwards, it can also be converted to electric power.

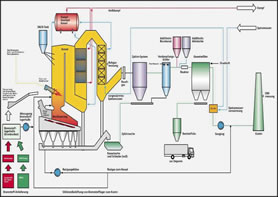

The flue gas generated during incineration is cleaned using a state-of-the-art flue gas cleaning process in conformity with the local statutory requirements.

Thermal utilisation of recycled waste paper

In the paper industry, some 10 to 20 percent of the waste paper introduced into the recycling process is left over as residual material depending on the process used.

Developing a concept that not only guarantees utilisation of these residual materials in line with current environmental legislation, but also makes considerable savings in respect of primary energy. This is achieved through thermal utilisation of the residual materials in a combined heat and power (CHP) generation process, in which the residual materials are utilised thermally by being combusted in a firing and boiler plant.

This combination of thermal utilisation with a CHP generation process significantly reduces emissions and their impact on the environment. In addition, the amount of waste dumped in landfill sites is significantly reduced, as are the costs of disposing of such waste.